- #Cnc usb controller software download how to

- #Cnc usb controller software download drivers

- #Cnc usb controller software download code

- #Cnc usb controller software download windows

Since many desktop PCs and all the notebooks no longer have a parallel port, we thought to a solution that will be described in these pages, and that enables to directly drive it via USB, and therefore by means of all the modern computers.

#Cnc usb controller software download how to

In this article we will show you how to use it, for the purpose of engraving printed circuit boards by means of an open source software and a refined hardware solution that enables the management via USB, from the PCs that do not have a parallel port.Īs with most CNC machines, even ours is supplied with a 3-axes control board that is interfaced to the parallel board, so that it is possible to drive it by means of software of the Mach 3 kind, that converts the G-code into pulses that are directly produced on the parallel port.

It is then surely possible to work with wood and, without overdoing it, it is possible to engrave (but at a low depth) aluminium plates. This machine, that stands out for the excellent value for money (which is suitable for an amateur CNC machine) has been thought mainly for engraving plaques (such as those for the mailbox, the intercom, the door) and plastic elements (even in POMs, Delrin included). In this post you had the chance to learn about and to evaluate our new CNC milling machine, equipped with a 9,000 rpm electro-spindle and with a compact PVC chassis, and available in assembly kit.

#Cnc usb controller software download drivers

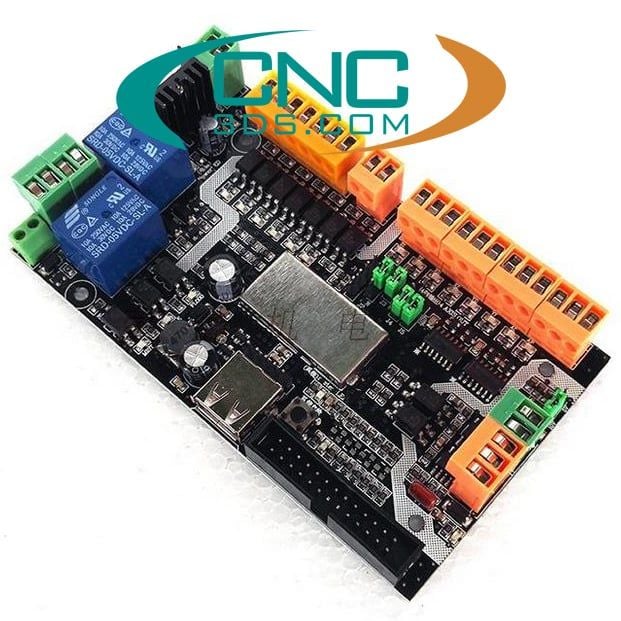

The UC100 is the result of a 2 years hard development and testing cycle and it implements linear and arc interpolation routines with trajectory planner, communication routines, limits and homing functions handling and it has nearly all the functions (with some limitations) as what Mach3 supports with the LPT port driver.īecause of using a high speed DSP core the UC100 making the interpolations and other timings much more precise as Mach3 could ever do using it's standard LPT port driver and because the time critical tasks are no more done on the PC side, but on the UC100 controller the PC's CPU time usage is much lower and the risk of overloading the PC resources lowers with factors as the UC100 has a long enough data buffer so that it can handle a 100% CPU usage and overload for some seconds without interrupting the motion and the G-code execution.įor these reasons it is also possible to use a much slower and cheaper computer together with the UC100 as what is needed for Mach3 if using the LPT port drivers and this can even lower the system's overall cost.Let’s print the PCBs by means of our CNC machine, that this time has been fitted with a controller that connects to a PC via USB, that draws the control signals and that regenerates timed pulses, simulating the parallel port. The UC100 has a look as if it was a “simple USB to LPT port converter module”, but it is much more than this. The UC100 controller connects to the PC via the USB port and this kind of port is more modern as an LPT port and exists on all today's computers.

#Cnc usb controller software download windows

The UC100 motion controller overcomes these problems with removing all time critical tasks from the control computer and Windows and executing all these tasks on inside it's own high speed DSP control chip outside the PC.

#Cnc usb controller software download code

If the computer gets overloaded by Mach3 or by running other software(s) in the background may leads to a lagging of the G-code code execution to even a falter in the motion interpolation which may lead to a catastrophic failure of some applications.Īnother problem with the LPT port is that in today's informatic technology this kind of port is no more used and is a dying out device and non of the new laptops having this kind of port built in anymore.

As the output signals frequency gets higher with using todays more and more advanced motor control electronics Mach3 needs the more processor time of the computer. Windows is not a realtime operating system and therefor it is a difficult and CPU time consuming task for Mach3 to generate these signals in a precise manner. Mach3 in default working the the computer's parallel (printer) port and sending all signals via this port. Mach3 is a popular CNC machine tool control software running on desktop computers and laptops under Windows operating system. Product description and background of working

USB CNC motion controller to use with MACH3 software ,ġ.

0 kommentar(er)

0 kommentar(er)